Brierley Associates is proud to support the North American Society for Trenchless Technology’s NoDig 2024, providing our expertise and insights in technical sessions at the conference, April 14-18, 2024 in Providence, RI. If you want to learn more, here’s a link to the NoDig website.

Design and Construction of Six Microtunnels for GLWA 14 Mile Loop

Monday, Apr 15, 2024 | 10:30 AM – 10:55 AM

Presented by: Kurt Breitenbucher, Thomas Pullen, Mike McReynolds

The existing Great Lakes Water Authority 14 Mile Water transmission main was not part of a looped system and experienced catastrophic failures in 2017 and 2021. These outages significantly impacted water service to communities in the Northwestern Detroit metro. GLWA commissioned a new pipe to add redundancy by creating a loop and tying it into an existing main on 8 Mile Road. A majority of the project utilized Michigan Department of Transportation right-of-way, including a crossing under a major interstate highway. This project dealt with the challenges of six tunnels under one set of contract documents. Each tunnel crossing had varying stakeholders, design challenges, and geotechnical conditions. Ultimately 3 support excavation types were used (soldier pile and lagging, steel sheeting, and trench boxes) for the tunnel shafts, and three tunneling methods (slurry Microtunneling, Pipe Jacking with TBM, and hand mining) were used to excavate the tunnels. The contract documents offered flexibility for accepted methods of shaft and tunnel construction, depending on ground conditions. This allowed the contractors to bid on the project with multiple combinations of allowable shaft and tunnel construction techniques. Additionally, the instrumentation and monitoring requirements of this project were a success due to the active participation and communication of the contractor. This was key to mitigating tunneling and shaft -induced settlement, and protecting key stakeholder assets. This paper will discuss design, challenges during construction, and the lessons learned for this major infrastructure project.

Tunneling for Clean Solutions for Omaha

Monday, Apr 15, 2024 | 4:00 PM – 4:25 PM

Presented by: Kyle Friedman (Brierley), Nick Strater (Brierley), Steven Stuempfig (Burns & McDonnell), Glen Wheeler (JW Fowler)

The Forest Lawn Inflow Removal and Outfall project is located in the Minne Lusa Basin and is intended to remove and/or control inflow into the existing combined sewer system. Stormwater flows from Forest Lawn Creek will be directed to the Missouri River during all rain events providing additional capacity in the local collection system and reducing the potential for back-ups into basements and street flooding. The project includes 13,000 linear feet of new storm sewer and 7,500 linear feet of new sanitary sewer winding through a residential area. Along Weber Street, trenchless technologies were required to install a section of the storm sewer that, due to grade requirements, would have required open cut trenches up to 40 feet deep. This section required 1,300 linear feet of 96-inch HOBAS pipe to complete the alignment and presented unique challenges of tunneling with soft, highly fine grained Loess soils while managing potential mixed face conditions with undocumented fill. This presentation will highlight the challenges of the construction and review risk mitigation measures taken by the City to manage risk and costs for the project.

Kyle Friedman detailed this project in Trenchless North America.

Drilling in Paradise – The Race to Replace Aging Pipelines Along Florida’s Oldest Causeway

Tuesday, Apr 16, 2024 | 8:00 AM – 8:25 AM

Presented by: Brian Dorwart (Brierley), Taylor Bomarito (Hazen and Sawyer), Joshua Preston Farmer (Hazen and Sawyer)

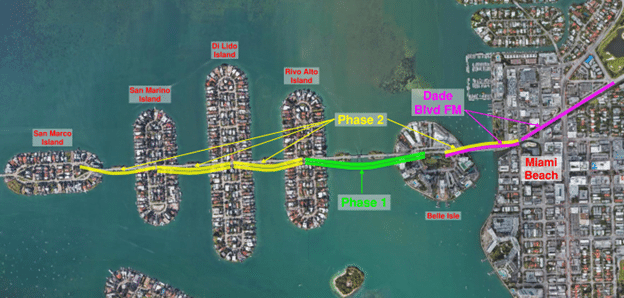

The City of Miami Beach has 28 aerial water/sewer mains along Florida’s oldest causeway, the Venetian Causeway. The corridor consists of ten islands connected via ten bridges in Biscayne Bay, one of Florida’s most protected water bodies. In response to pipeline failures, the City accelerated design and construction of replacement pipelines on an emergency basis. Exacerbating the challenge is Miami Dade County’s plan to replace the 1920’s era bridges in the near-term, which disallowed the use of replacement aerial pipelines. The project’s Horizontal Directional Drilling (HDD) required constructed accuracy near the limits of feasibility to meet all project constraints within the extremely tight corridor. Careful coordination was required with the County’s replacement bridge designers to avoid conflicts with future infrastructure. The increasing usage of HDD in urban environments puts greater emphasis on guidance accuracy and as-built precision, necessitating more careful review of project alignments and usage of cutting-edge technologies. The project’s design utilized acceptance criteria through the use of specific critical alignment locations and provided specifications for construction methodology and sequencing to accommodate the current and future planned construction as well as technological limitations of pipe installation by HDD. Historically, when limit-pushing technologies have been applied under complex conditions, risk-sharing techniques have often been employed within construction contracts to fairly mitigate and balance risk. Risk-sharing methods were developed for this project to mitigate risk as practicably as possible and allocate residual risk to the party most capable of managing that risk along with planning for intolerable outcomes.

Double Trouble: A Tale of Twin Water Main HDD Installations with Two Pipe Types While Drilling in Tight Places

Tuesday, Apr 16, 2024 | 4:30 PM – 4:55 PM

Presented by: Dave Sackett (Brierley), Jim Williams (Brierley), Robert Tatum (Underground Solutions, Inc.)

Twin water mains were installed along Pineda Causeway from Palm Shores to Satellite Beach, Florida totaling approximately 29,000-feet. The cities of Melbourne and Cocoa shared the responsibilities to fund, design, and build the water mains. The six jack and bore crossings consisted of 30″ steel casing ranging from 85 linear feet (LF) to 180 LF. The nine HDD crossings ranged from 1048 LF to 6177 LF including four subaqueous crossings beneath the Indian and Banana Rivers. The original plan was to install Fusible PVC (FPVC) for the HDDs, but due to supply chain issues procuring the pipe during the height of the Covid crisis, portions of the pipe installed in the trenchless crossings were 18″ DR9 HDPE; however, for the longest crossings beneath the Indian River, the pipe installed was 16″ DR14 FPVC. The Indian and Banana Rivers are tidally influenced, shallow water, and environmentally sensitive. Groundwater levels ranged from river level to El +5. Artesian conditions were encountered beneath the Indian River. The General Contractor, Quality Enterprises, used American Auger DD1000RS and DD550RS drilling rigs for the intersecting pilot holes. Pipe pullbacks ranged from approximately 8 to 24 hours to perform. For the subaqueous HDD crossings, the pipe was installed to elevations ranging to El -90 ft. Installation of the water transmission mains was completed in mid-2023 without HSE-related incidents. The paper will discuss geotechnical conditions and site variability, preparation of calculations packages, pipe selection criteria, drilling equipment and methodologies, and field results.

Microtunneling for Electric Cables in Providence – A Case Study

Tue Apr 16, 2024 | 5:00 PM – 5:25 PM

Presented by: Nick Strater (Brierley), Thomas Buonomano, P.E. (POWER Engineers)

A recent installation of new, below-grade electric cables required trenchless installation of a duct bundle below Route 146, a busy highway bringing commuter traffic to and from the northwest side of Providence. Shallow groundwater, and the presence of the sensitive “providence silts” required watertight work pits, and installation of the cable casing by slurry microtunneling. A 48-in diameter Centrifugally Cast Fiberglass Reinforced Polymer Mortar Pipe was selected for containment of the duct bundle. To ensure cable ampacity, and to facilitate heat transfer, the cable design required that the annulus between the casing and duct bundle be completely filled with thermal grout. This paper summarizes the geotechnical exploration and characterization program completed for the crossing, including test borings and lab testing. Design considerations are provided, including short and long-term pipe loading, and surface and below grade instrumentation requirements. Details of the thermal grouting operation used to fill the annulus of the casing are also presented, including duct testing and grout placement.