Project At-a-Glance

- Geotechnical investigation and Structural evaluation of unreinforced concrete lined tunnels

- Progressive Design/Build Contracting

- Finite Element Analysis models developed to assess ground-structure interaction

- Evaluation and implementation of several repair options to maintain in-service operations to deliver water throughout construction

Brierley Associates, as lead designer to Ballard Marine Construction, provided preliminary engineering for repairs to extend the life of Great Lakes Water Authority’s critical water conveyance assets. Initial elements of work included assembly and review of record drawings, prior inspection and repair documents. This was followed by a geotechnical investigation campaign utilizing conventional drilling, CPTs and in-situ pressuremeter and flat-plate dilatometers, and groundwater testing. Additionally, geotechnical instrumentation was installed gather baseline data relative to tunnel distress prior to construction.

Using the gathered data, Brierley developed Finite Element Analysis (FEA) models to better understand ground-structure interaction, assess tunnel liner stability, and to support the detailed design for various repair options.

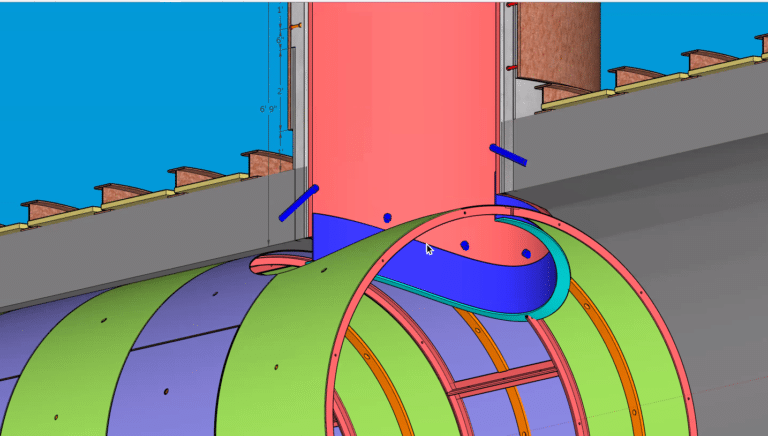

Working together with GLWA our team evaluated alternative solutions including: “in-the-wet” with divers, dewatered repairs with massive bypass pumping, and construction of parallel replacement tunnels with live connections and tunnel abandonment. At the Northeast and Springwells site locations, Brierley designed a repair option that included tunnel relining and new access shafts, which are to be constructed in live flow conditions. The lined portion of the tunnel consists of affixed stainless-steel liner plates with annular grout injected in fully submerged conditions. At the Pennsylvania site, tunnel rehabilitation was done using non-structural concrete crack repair by injecting a hydrophilic polyurethane resin grout into existing cracks.

To facilitate the tunnel repairs in the Northeast and Springwells tunnels, Brierley designed four new drilled access shafts, two for each tunnel. connected to the tunnels during in-service conditions using wet tap methods.

Throughout the entire investigation, evaluation, design, and repair process, extensive coordination was required for collaborative design, site access, work in active flow with respect to plant operations, and to prevent impacts to GLWA’s operations.